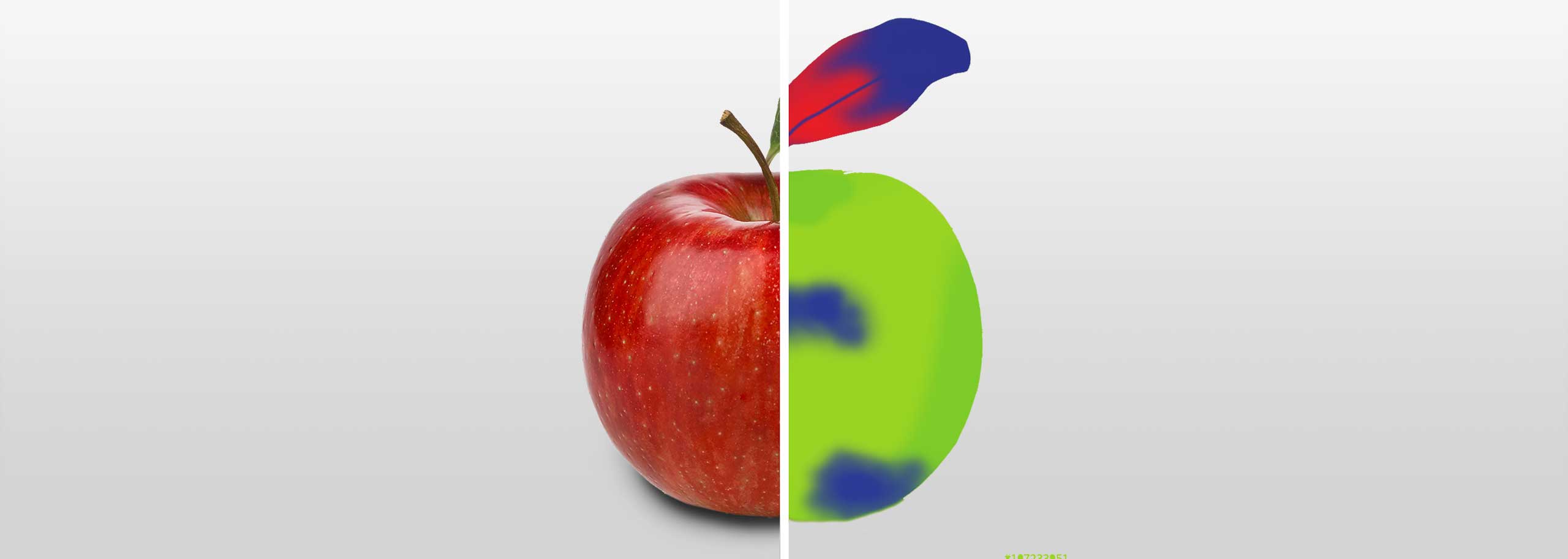

Machine vision is the application of computer vision and analysis. Vision systems are programmed to perform narrowly defined tasks such as counting objects on a conveyor, reading serial numbers and inspecting objects for surface defects. Common uses of this technology extend to many industries including semiconductors, automobiles, food, recyclable materials and pharmaceuticals. In many instances, machine vision performs roles previously handled by human beings. Often times, they are implemented in inspection systems requiring high speed, high magnification, 24-hour operation and/or repeatability measurements.

Optical Filters Play an Important Role in the Function and Effectiveness of Machine Vision Systems.

By selectively isolating the spectral signature of various objects, they can be carefully analyzed and inspected. Frequently, the sensors used in machine vision have detection wavelengths over a broad range of the spectrum from the UV through near infrared. Without proper filtering and attenuation of unwanted signal, the sensors would be ineffective as the registration of unwanted light creates high levels of noise. Filters increase the signal to noise ratio allowing for proper discrimination of desired wavelengths while blocking all other light.

As machine vision systems are used in a wide range of applications and cover a large portion of the electromagnetic spectrum, Omega Optical offers filters ranging from 410nm through 790nm. These filters are applicable to the configuration of many instruments and, with the ability to custom design and manufacture filters as well, we can meet the needs of any application.