Longpass filters (sometimes called edge filters, long pass, long-pass, or LP) and Shortpass filters (sometimes called edge filters, short pass, Short-pass, or SP) transmit wavelengths above (LP) or below (SP) a certain wavelength. This wavelength is called a cutoff wavelength for shortpass filters and a cuton wavelength for longpass filters. LP filters can be used instead of bandpass filters in fluorescence applications to maximize signal when using a single fluorescent label, or to block the laser in Raman applications. SP filters are often used in digital cameras to block undesired near-infrared (NIR) signals from reaching the camera. These types of filters are often called hot mirrors. Bandpass filters can be obtained by combining the appropriate LP and SP edges. This is the basis of the RapidBand products.

Jump to-

- Required Specifications for longpass and shortpass filters

- Types of longpass and shortpass filters

- Specialty longpass and shortpass filters

Required Specifications for Longpass and Shortpass Filters

Average %T and wavelength range of the transmission region are specified by the customer.

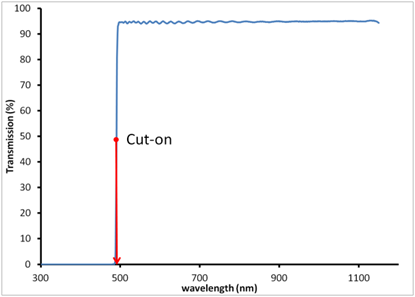

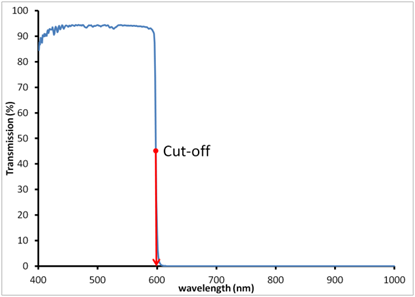

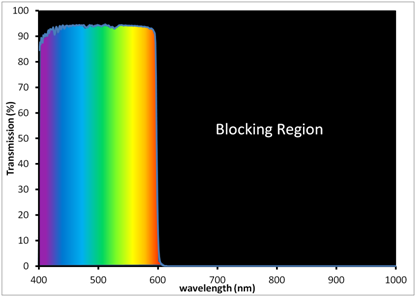

Cuton and Cutoff wavelengths designate the wavelength at 50% of the peak transmission (the rising edge for a LP, or falling edge of a SP illustrated below on the transmission curves).

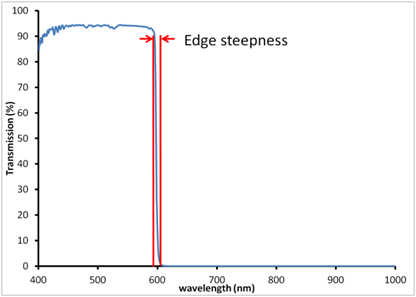

Edge Steepness describes the transition from blocking to transmission in more detail (nm). Specify the transmission range of interest (i.e. 3 nm from 90% T to 10% T, or 10 nm from 50% T to OD4).

Blocking specifications determine the wavelength range (nm) and blocking (OD) of unwanted light. Optical density (OD) is a log scale relating the transmitted to incident light. Typically, the wavelength range for blocking is dictated by the response curve of your detector. However, extended blocking is not required for some applications (for example laser-cleanup or Raman filters) where unwanted signals are only present in a limited wavelength range.

Types of Longpass and Shortpass filters

-

Rapid Edges

- LP edges available every 10 nm from 400-700 nm

- Low wavelength side blocking to 400 nm

- SP edges available every 10 nm from 450-700 nm

- High-side blocking to 1100 nm

- Selected other wavelengths are also available

- Size 25 mm rounds

-

Standard Longpass

- Coatings get thicker and more expensive at higher cuton wavelengths and for extended blocking ranges

- Cuton wavelengths 250-1200 nm

- Size 2-90 mm

-

Standard Shortpass

- Coatings get thicker and more expensive at lower cutoff wavelengths and for extended blocking ranges

- Cutoff wavelengths 400-1200 nm

- Size 2-90 mm

-

UV filters

- The manufacture of UV filters poses a unique set of challenges. Click here to learn more.

- Wavelengths 175-400 nm

-

Raman Edge filters (longpass)

- For blocking of the Raman laser line

- Edge steepness (90%T to OD6) within 300 cm-1 of the laser line

- Size 2-25 mm

Specialty Longpass and Shortpass Filters

Omega has produced limited quantities of these specialty filters for individual customers. We welcome the opportunity to work with you on your product.

-

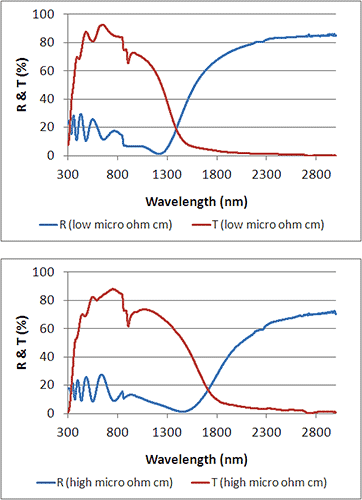

Transparent Conductive Oxides (TCOs) as SP filters

- Transparent conductive oxides (TCOs) offer a combination of visible transmission, infrared reflectance, and electrical conductivity.

- The figures show two examples for indium tin oxide (ITO). The top figure shows the optical properties of highly conductive ITO, while the bottom figure shows the properties of less conductive ITO. The R&T curves and the electronic work function change as the alloy composition is varied.

- Omega has developed several material systems for TCOs. Download the flyer here.

- Applications include electrostatic control, heated windows, and photovoltaic research

- They can also be used to extend the reflectivity of hot mirrors into the IR.

-

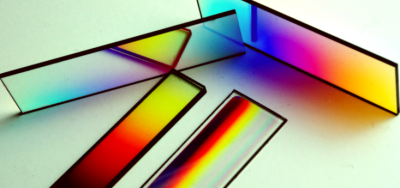

Linear Variable filters

Download the LVF flyer - Linear variable filters are LP or SP filters that change cuton or cutoff wavelength across one dimension of the part. They can be used as rudimentary spectrometers or in order-sorting applications. The spectral properties of the filter must be specified as described above as well as the gradient (nm/mm) across the part. Omega has achieved gradients of up to 50 nm/mm across the visible spectrum using custom coating techniques.

- This work has been presented at Photonics West

-

Patterned filters

- Patterned filters are produced by dicing filters into small pieces and reassembling them on a backing glass with optical epoxy or depositing through metal masks, or with photolithographic methods.

- Omega is a subcontractor on a project that involves patterned coatings on the tips of fiber optics. Read our recent Photonics West paper.

-

Coated fiber tips

- Omega is an expert at applying filters to the tips of optical fibers.

- Hard oxide and soft-coating designs are available.

- Learn more about our fiber-tip coating capabilities.