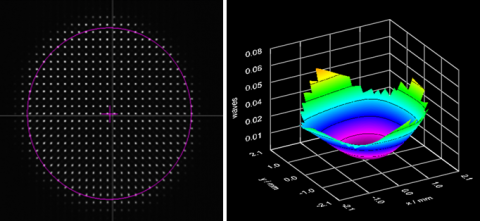

In this final installment of “Making Waves” we will discuss the Shack Hartmann wavefront sensor and its use for flatness measuring at Omega.

Unlike the interferometric techniques described last month, which require mathematical transforms of the image to calculate the wavefront, the Shack Hartmann measures wavefront directly using a geometric method. The sensor is a camera with an array of microlenses applied in front of it. A collimated light beam enters the array and is converted into a series of spots on the detector. When the wavefront is perturbed, the positions of the spots in the array change. The wavefront is calculated from deflections from the collimated position (reference).

Data from the Shack-Hartmann looks like a perturbed surface, with bumps and wrinkles corresponding to the wavefront reaching the detector. It does not generate an interferogram. Our instrument is set up to measure both RWD and TWD on parts up to 3 inches in diameter down to about ½ wave. It has advantages over a laser-based interferometric system because we can measure wavefront at any visible wavelength. For that reason, we use it regularly to measure coated parts that have spectral features that don’t allow measurements at a specific laser wavelength (as in a Zygo).

Shack-Hartmann wavefront sensors are being widely deployed in adaptive optics applications such as astronomy, where the mirrors need to be adjusted in time to account for wavefront distortions caused by slight refractive index changes in the atmosphere. Adaptive optics can also be used in underwater or biological applications to keep images in focus in a myriad of changing conditions.

Click to learn more about wavefront and flatness testing at Omega.